Solution N°1

PerfTrak is a solution for monitoring and improving machine performance. This decision-making tool combines the most modern technologies (Bluetooth Low Energy, IoT, Android, WIFI) with the principles of Lean Management.

1 Measure the performance of any equipment

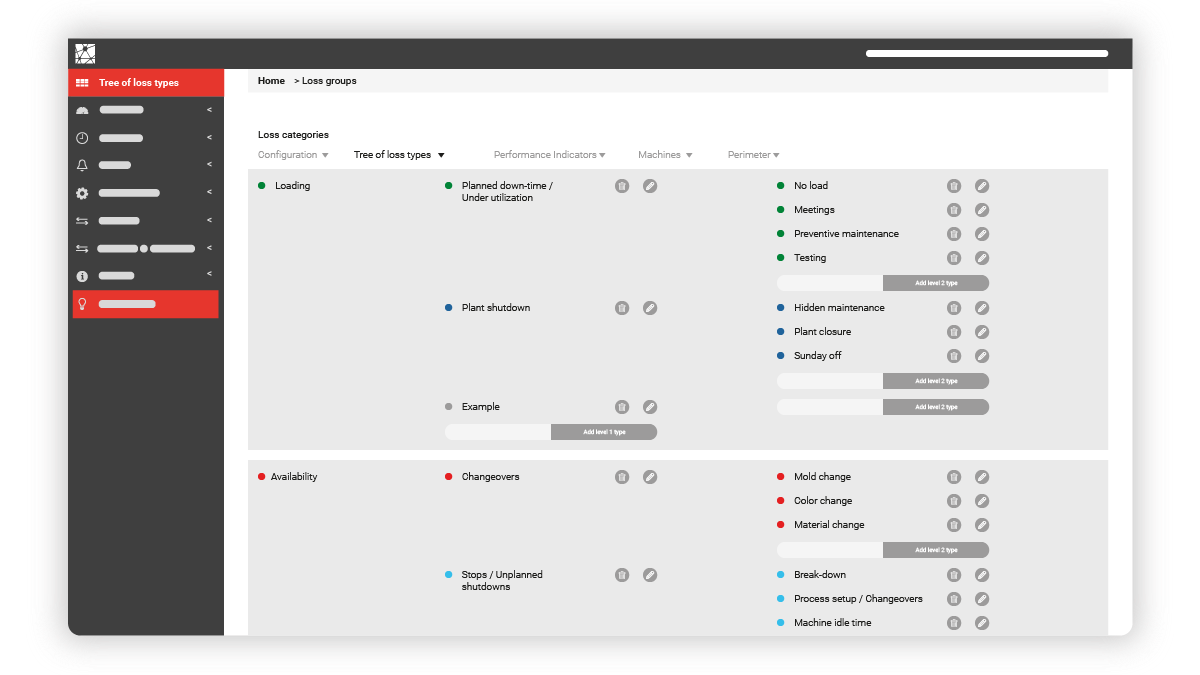

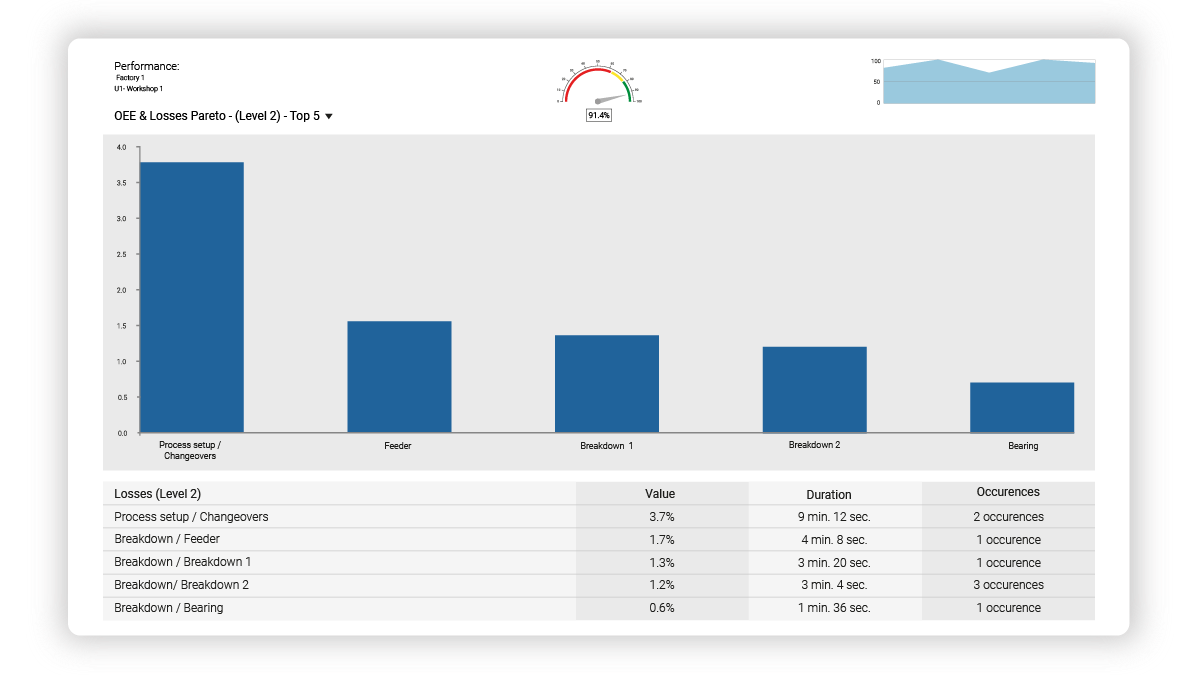

2 Identify the causes of performance loss

3 Reduce equipment downtime

4 View information on a consolidated perimeter

Operating principle

PerfTrak makes possible to recover, in real time, the operating state of a device and then identify the performance losses. Then we involve the operators in the qualification of the losses.

All the informations collected are automatically consolidated, analyzed and returned to the supervision website to allow teams to make the most relevant action plans.

Automated acquisition

data by the electronic module

Entering the causes of shutdown

by the operator on the tablet

Visualization in

real time

data on the website

Principle of installation

Compatible with all equipment, modern or old, cycle time or “start & stop”, PerfTrak can be installed in three stages: connection of the module to an existing or added sensor to obtain the operating status of the machine, installation from the tablet close to the connected equipment and

configuration via the supervision site. The total installation takes less than an hour per machine to obtain a 100% functional product. You just need a wifi terminal to install it.

Connect the module

to a sensor

Install the tablet

on the production station

Configure website

and create the virtual factory

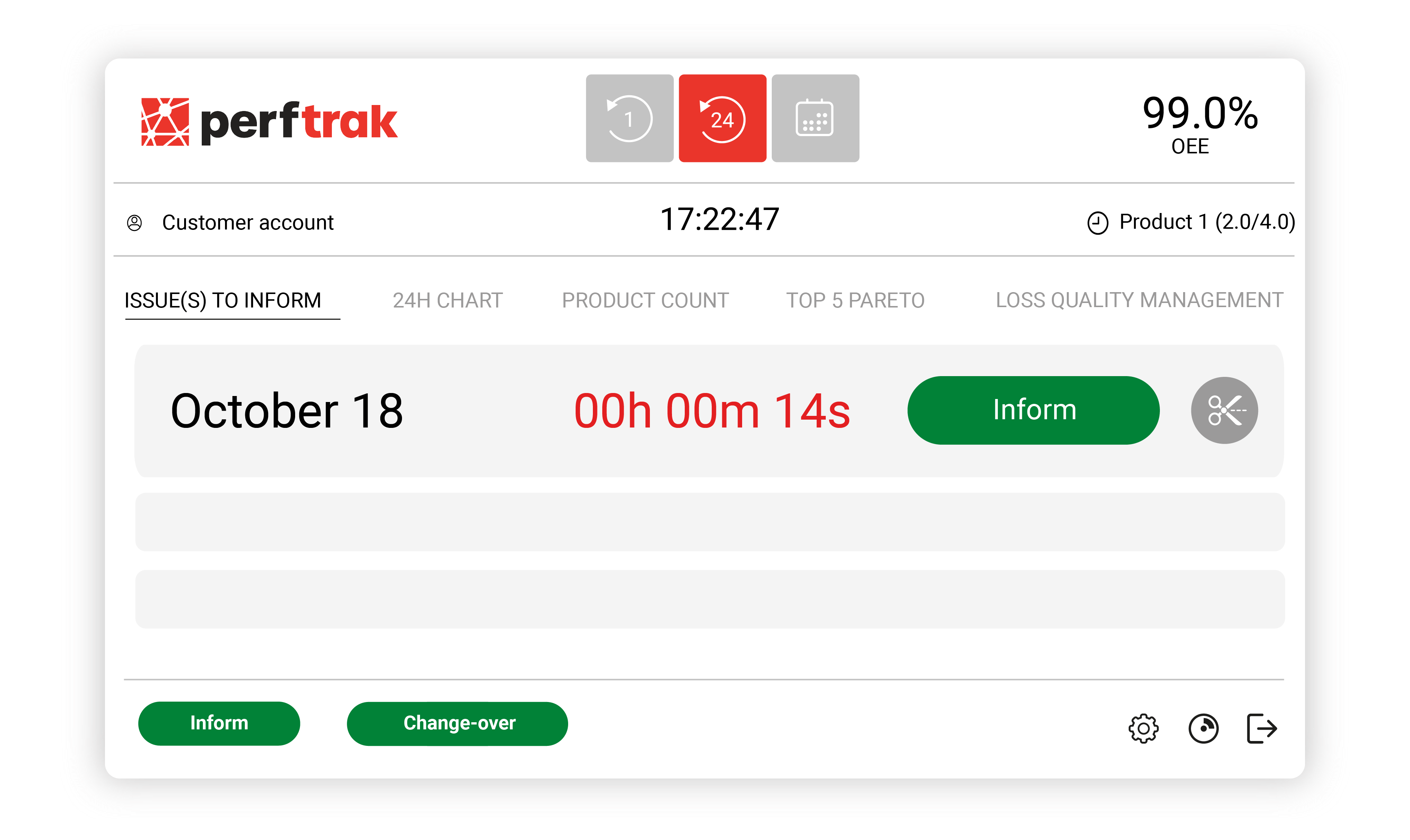

The tablet interface

The tablet interface allows operators to qualify the causes of shutdown, instantly and at the foot of the equipment from the causes previously defined on the supervision site.

This same interface also allows a simple, real-time visualization of key production information in the field (24-hour history, product counting, pareto of losses over the chosen interval, etc.)

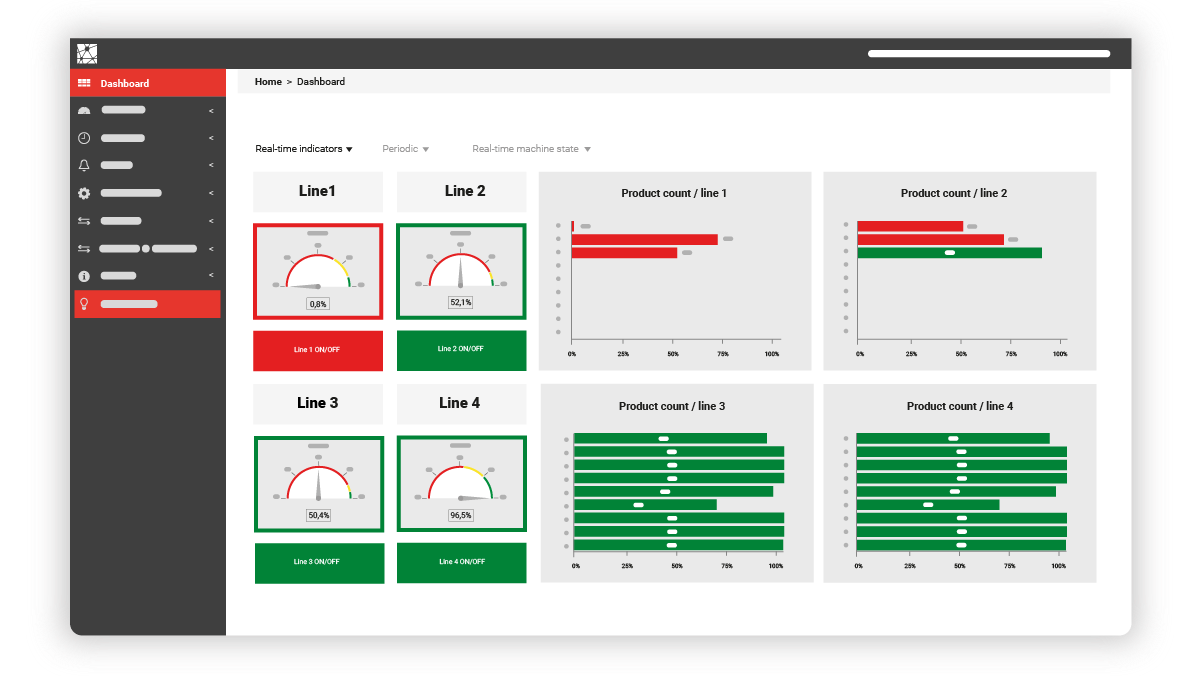

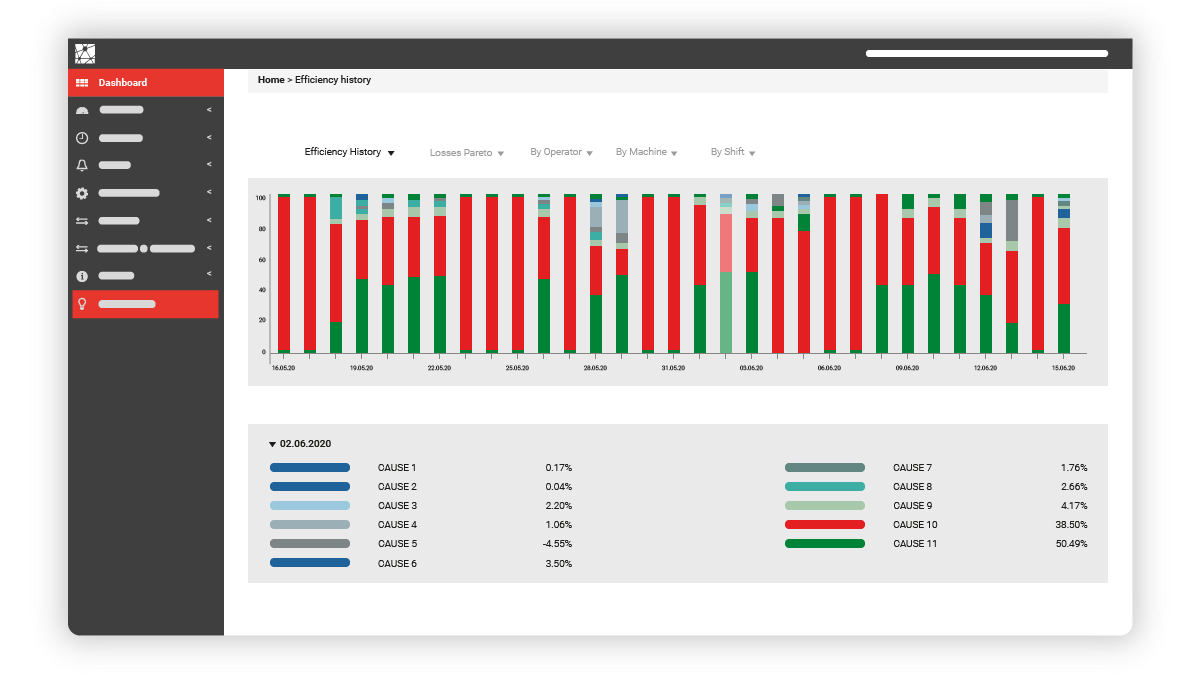

The supervision website

The supervision site, in addition to allowing the configuration of the systems, brings together a set of ergonomic and intuitive functionalities, to enable the teams to understand the performance losses and act autonomously for continuous improvement.

Some features: real-time dashboards, performance history for the chosen scope and period, product counting, manual and automatic reports, alarms by SMS or smartphone, etc.