The standard of the AFNOR regulation that we use and that our users can adapt on their situation

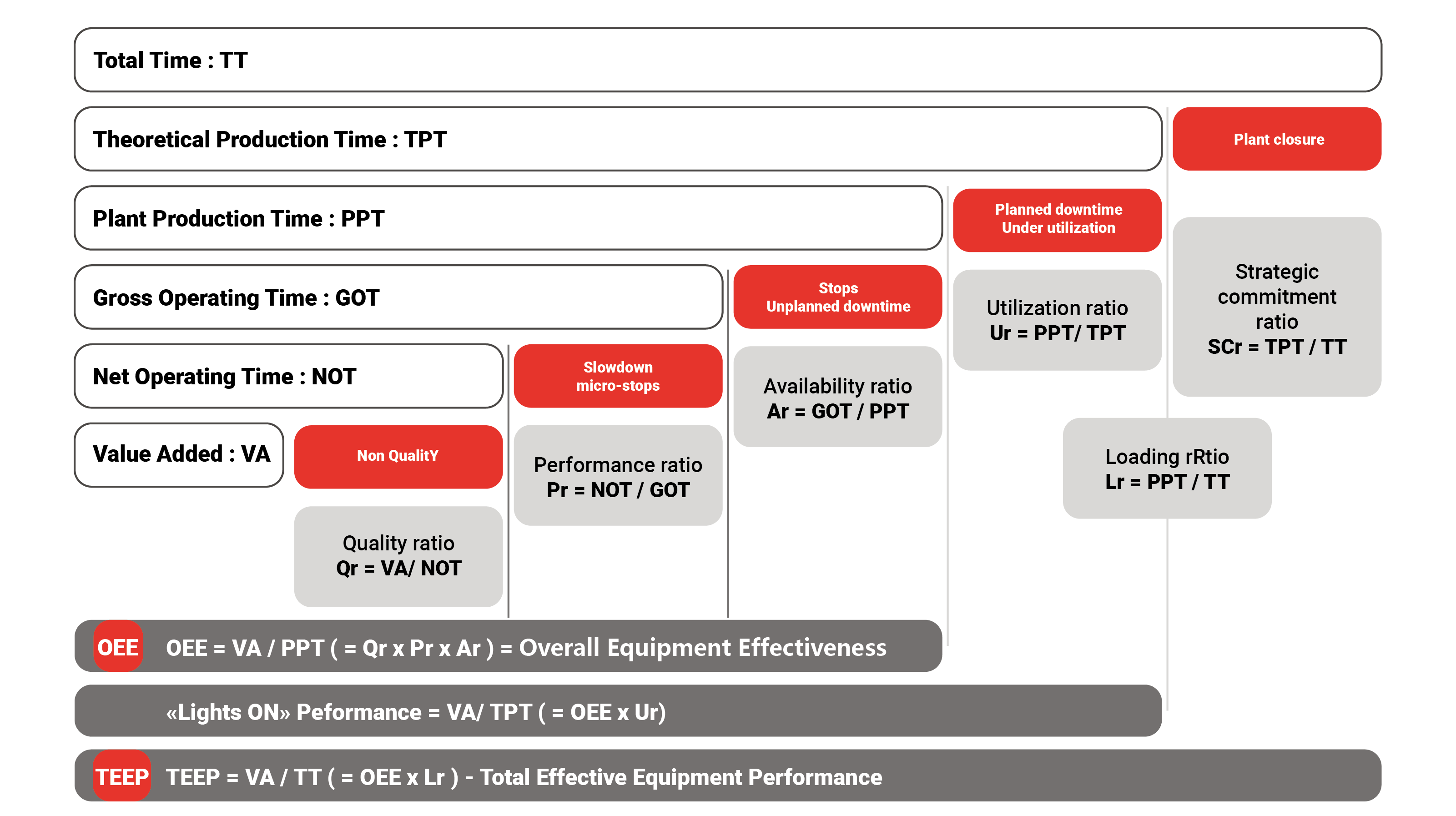

Seiichi Nakajima developed OEE (overall equipment effectiveness) in the 1960s to evaluate the effectiveness of a given manufacturing operation and it is now the most frequent indicator found in manufacturing industries. While OEE measures effectiveness against scheduled hours, TEEP measures effectiveness against calendar hours (24/7/365 days per year).

OEE and TEEP are not, however, absolute measures and are best used to identify priority improvement levers. The value of these indicators is relative to a baseline for a given piece of equipment and therefore specific to that equipment and not necessarily comparable across departments or plants. Maximizing OEE or TEEP doesn’t necessarily mean reaching the global optimum.

Indicators and causes of loss of performance

TEEPTRAK allows you to assign to each piece of equipment or area monitored a set of fully configurable categories of causes of performance loss. With the PerfTrak, QualTrak and PaceTrak solutions, these causes can be entered by the operator on his tablet when a production gap (machine stop, underperformance,…) is reported to him by the TEEPTRAK module.

These causes of losses will be linked to groups of causes that will make up the performance indicators. When constructing an indicator, certain groups of causes may be included or excluded from the calculation of the indicator.

Below : an example of a nomenclature of performance losses for each typical category of the OEE/TEEP indicator calculation.. To track an OEE (TRS), the categories “Downtime at the production site” and “Planned downtime” will not be taken into account in its calculation.