Solution N°2

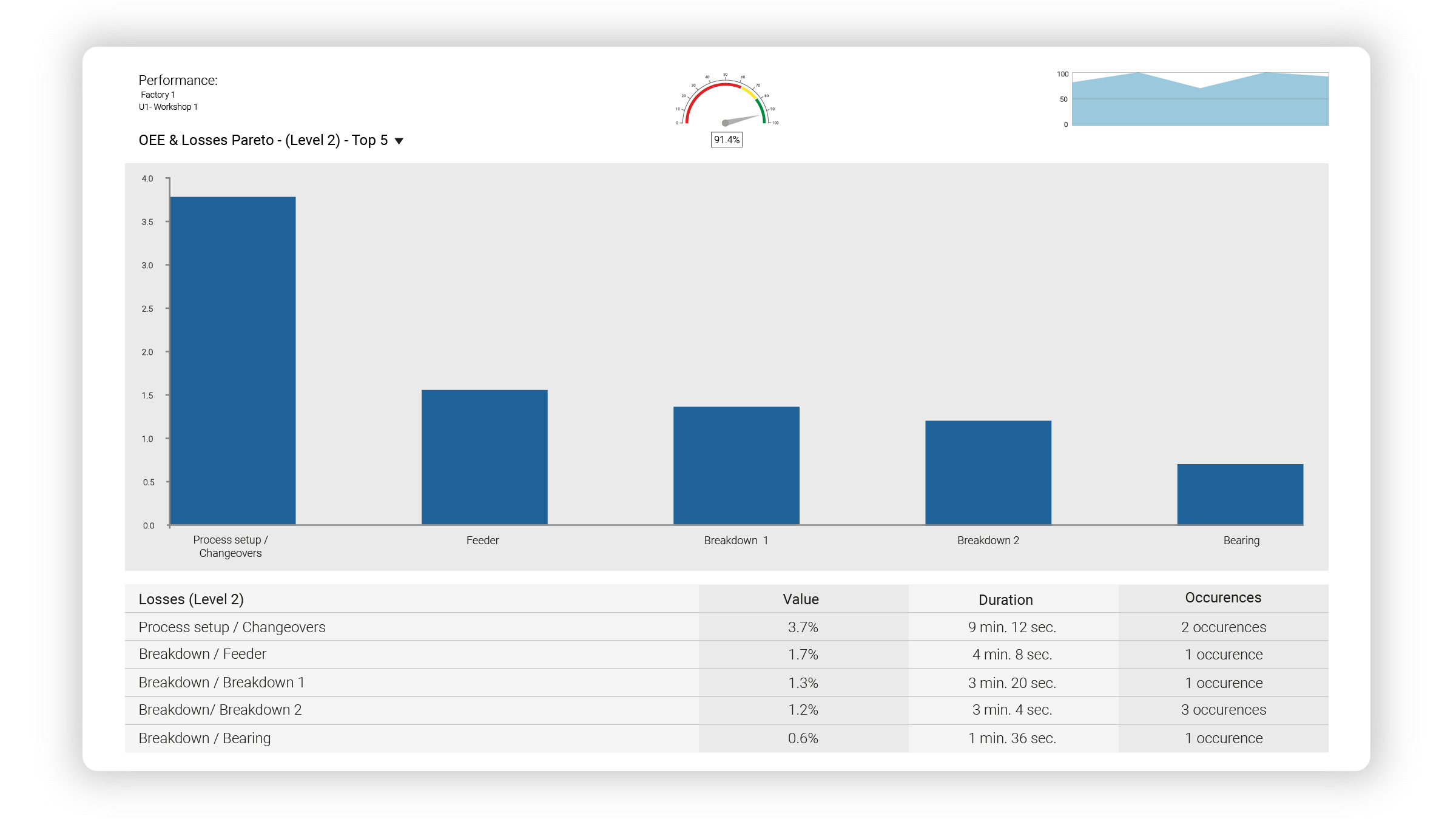

PaceTrak detects deviations in task completion time and requires operators to explain these anomalies, offering field teams the channels by which they can easily identify opportunities to improve their missions.

The objectives are to identify methods for better productivity while creating a motivating environment for the operators.

1 Measure the performance of different manual tasks

2 Identify opportunities for operator improvement

3 Reduce production downtime

4 View information on a consolidated perimeter

Operating principle

By detecting negative or positive deviations in task time and asking operators to explain the cause of these deviations, PaceTrak gives field teams the means to easily identify opportunities for improving their missions.

The objective is twofold: to identify the blocking points of achievement for better productivity while improving the working environment for operators to create a direct positive impact on their motivation.

Automated acquisition

data by the electronic module

Entered by the operator

causes of time gaps in completing tasks

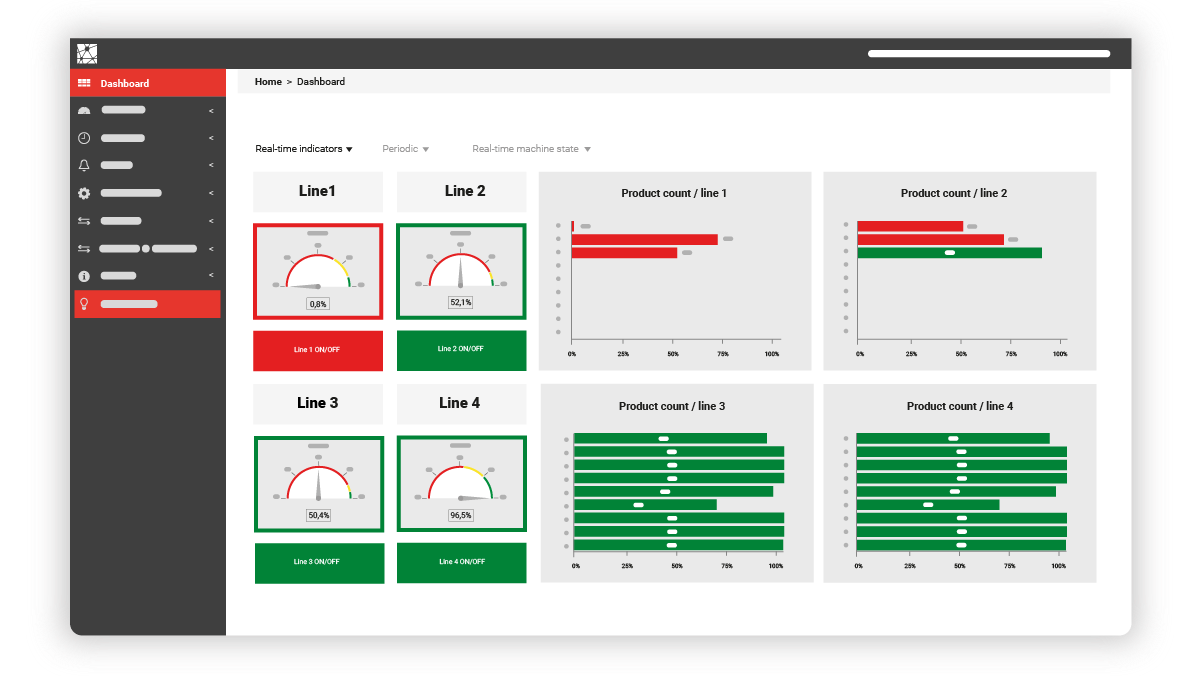

Visualization in real time

data on the website

Principle of installation

PaceTrak is available in automatic, semi-automatic and manual versions. With or without acquisition module. In manual, the operator declares the start and the end of his range or tasks.

In semi-automatic mode, we detect an electrical signal when starting or closing a task. In automatic version the starts and the end of a task are automatically recovered.

Connect the module

to a sensor

Install the tablet

on the production station

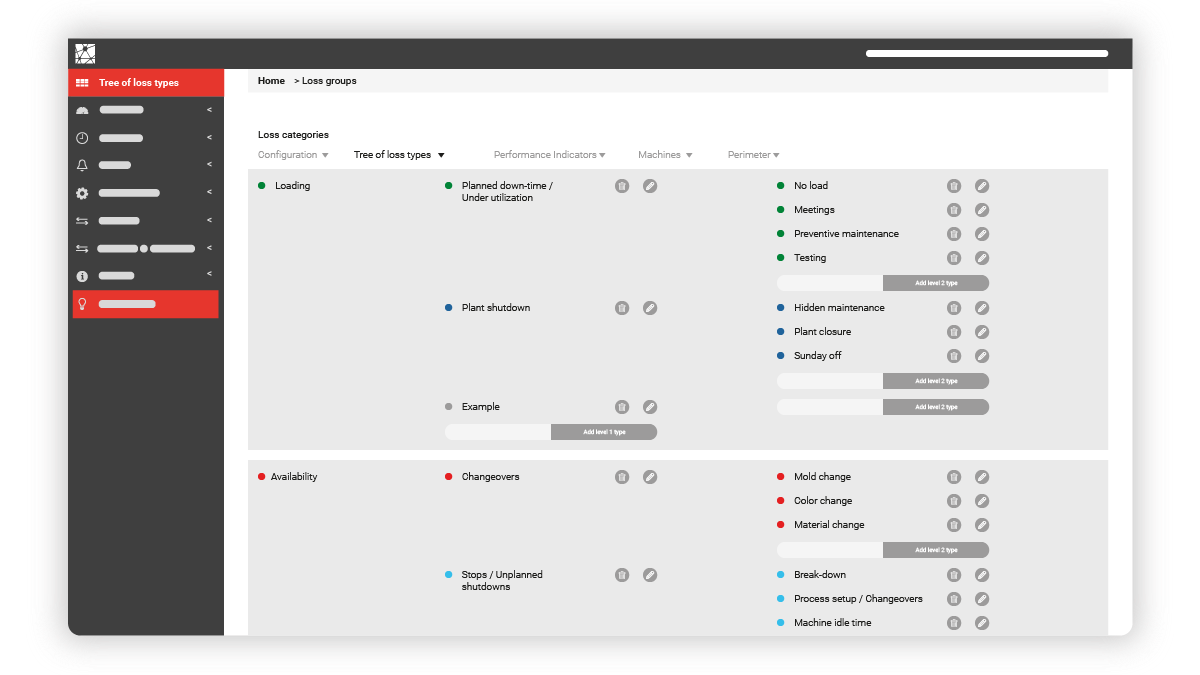

Configure website

and create the virtual factory

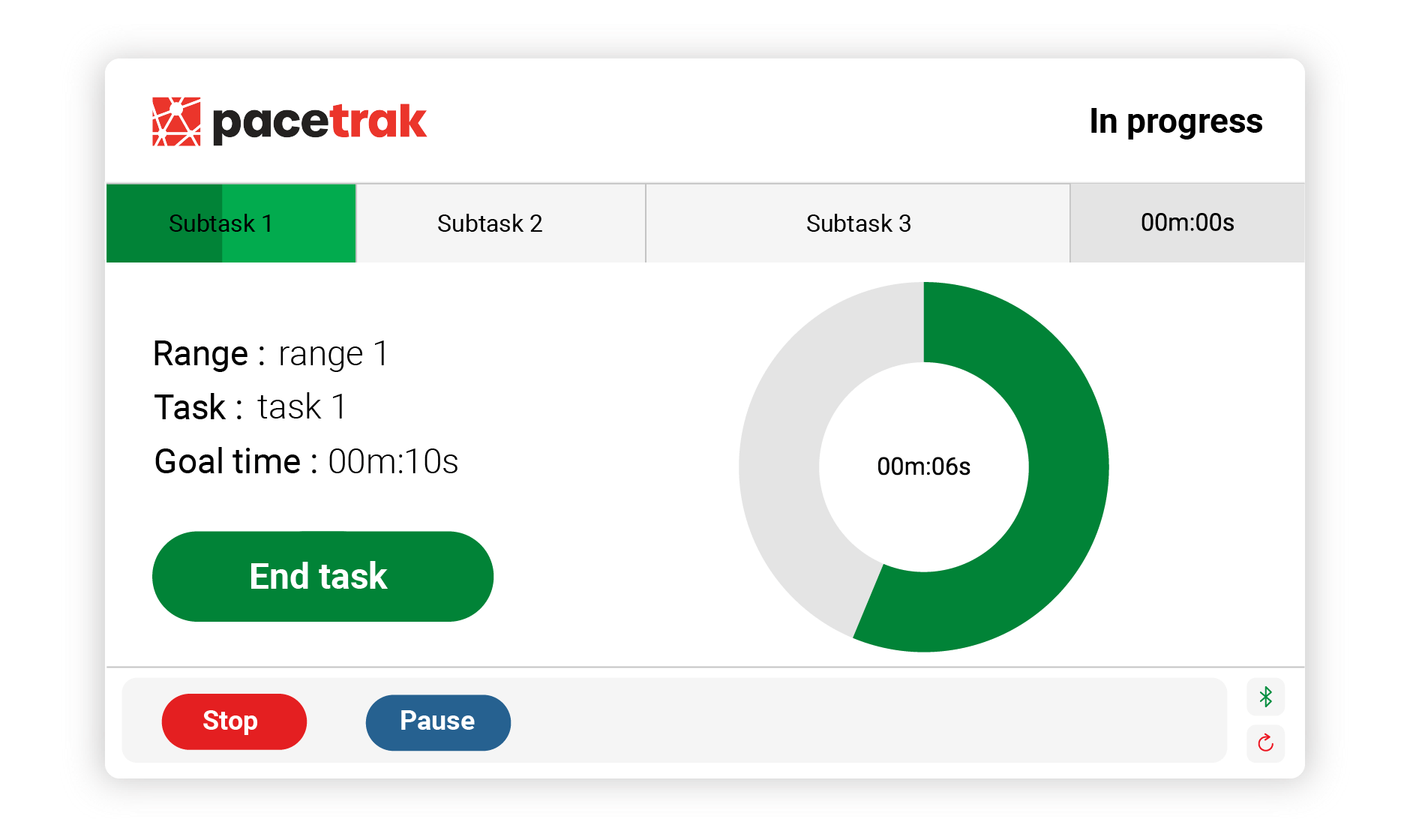

The tablet interface

The tablet interface allows operators to qualify deviations from the standard instantly while remaining at the workstation.

This interface is ergonomic and designed to avoid any waste of time.

The supervision website

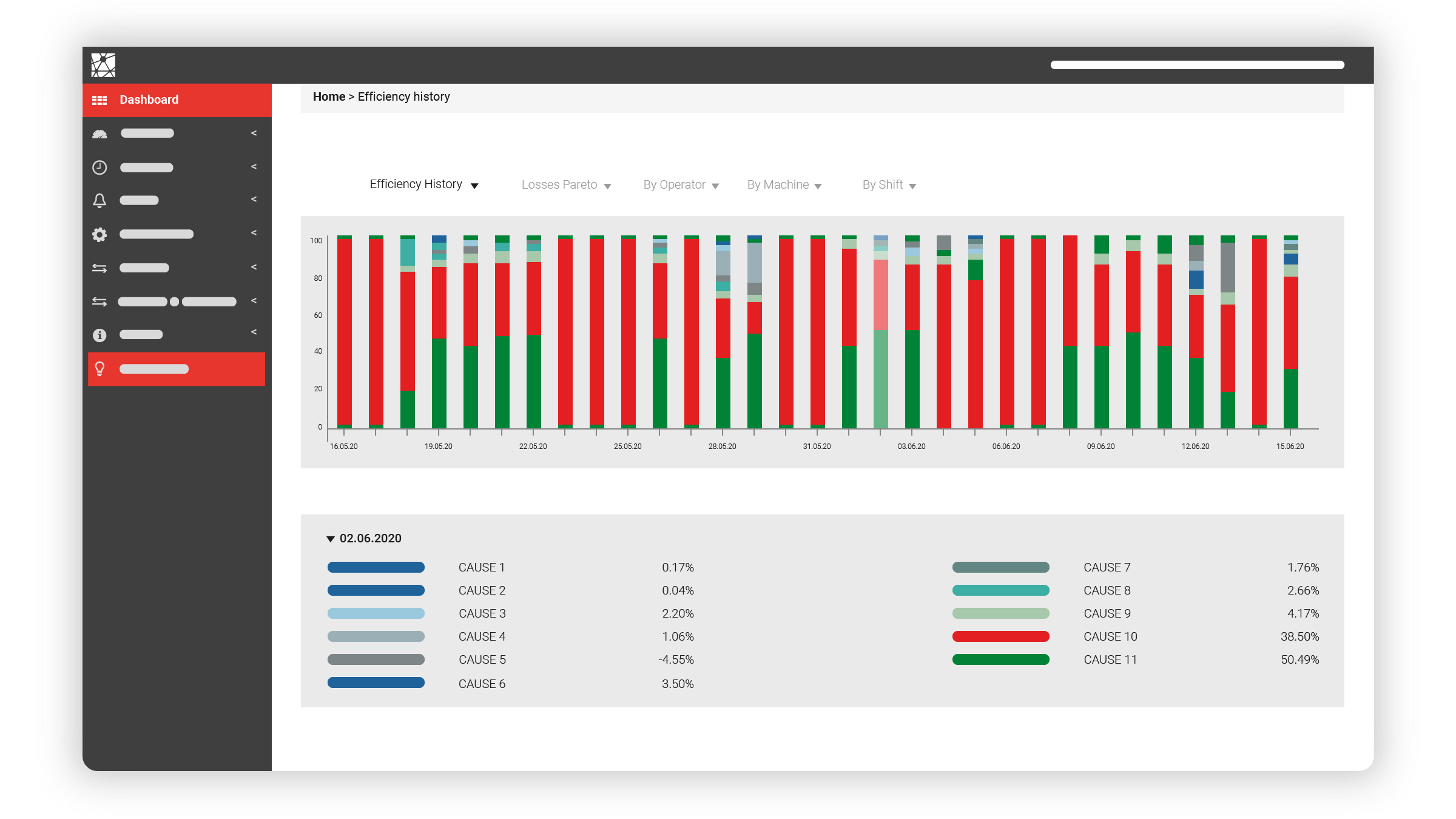

The supervision site, in addition to allowing the configuration of systems, brings together a set of ergonomic and intuitive functionalities, to enable teams to understand performance losses and act independently for continuous improvement.

Some features: real-time dashboards, performance history for the chosen scope and period, task register, manual and automatic reports, alarms by SMS or smartphone…