Solution N°4

A quality monitoring and improvement solution that applies the same data acquisition/analysis principles as PerfTrak or PaceTrak.

This tool allows you to perform analyzes at any time scale to quickly address quality problems. It allows to :

1 Quantify good and bad production

2 Identify the causes of non-quality

3 Know in real time the quality level

4 View information on a given perimeter and period

Operating principle

QualTrak records the quality level almost automatically and in real time. By quantifying production and utilising the information provided by operators explaining origin of losses,

analyses can be performed on command in order to quickly address quality issues. The level of interaction with operators is adjustable as needed.

Automated acquisition

data by the electronic module

Entered by the operator

of non-quality causes on the tablet

Visualization in real time

data on the website

Principle of installation

QualTrak is available in automatic, semi-automatic and manual versions. With or without acquisition module. In manual, the operator declares the number of bad pieces and their reasons. In semi-automatic mode, we detect an electrical signal when a piece arrives or leaves (good or bad output).

In automatic we detect the arrival of a piece and one of the two outputs via an external sensor or an electrical signal.

Connect the module

to a sensor

Install the tablet

on the production station

Configure website

and create the virtual factory

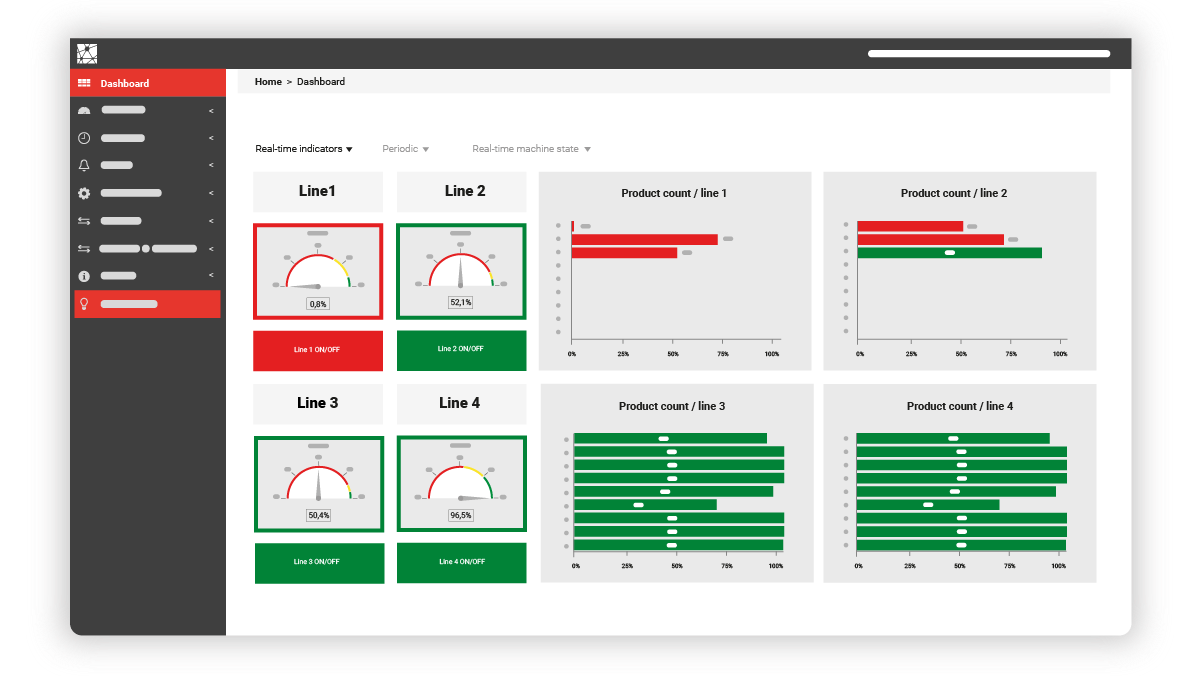

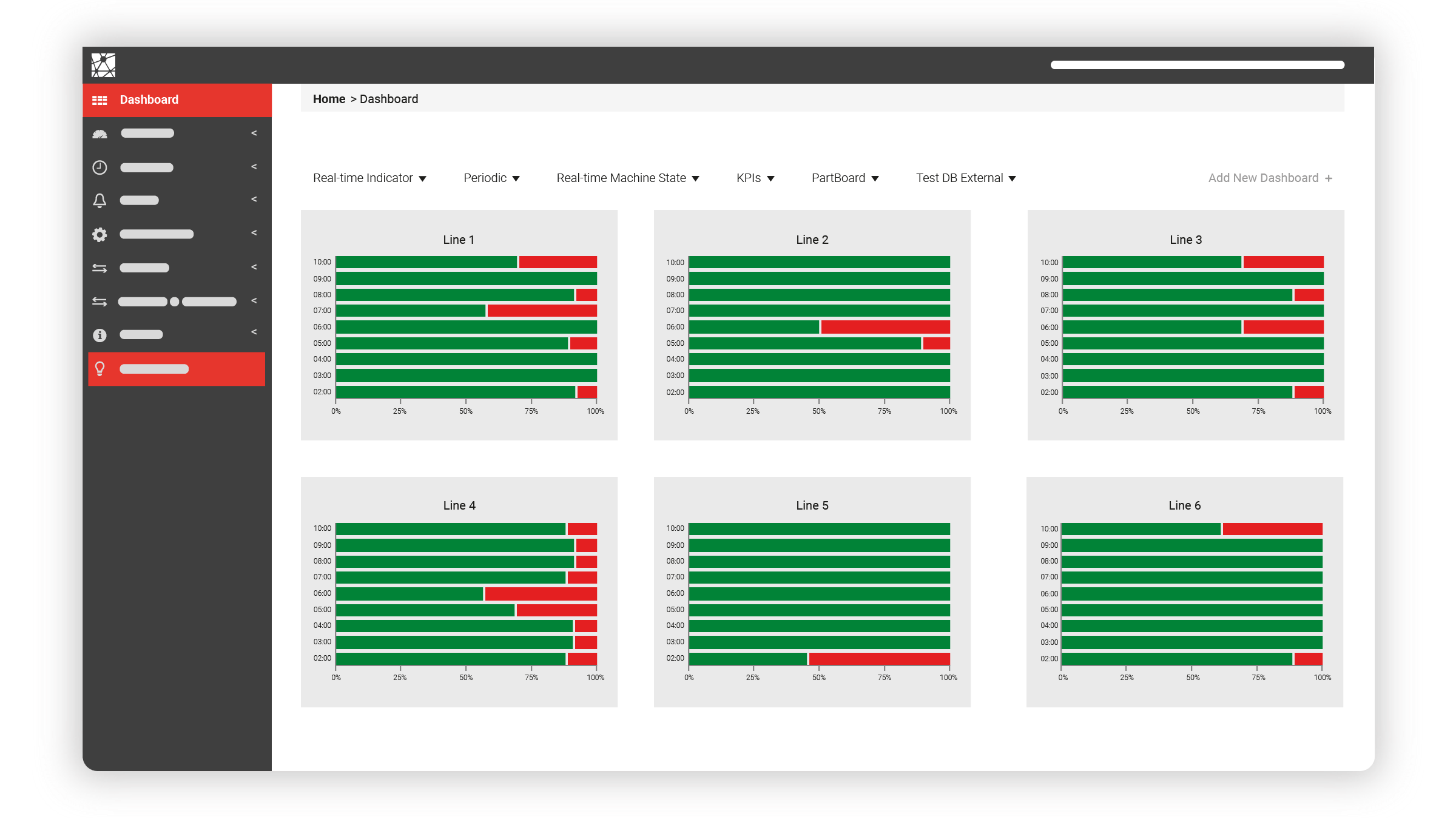

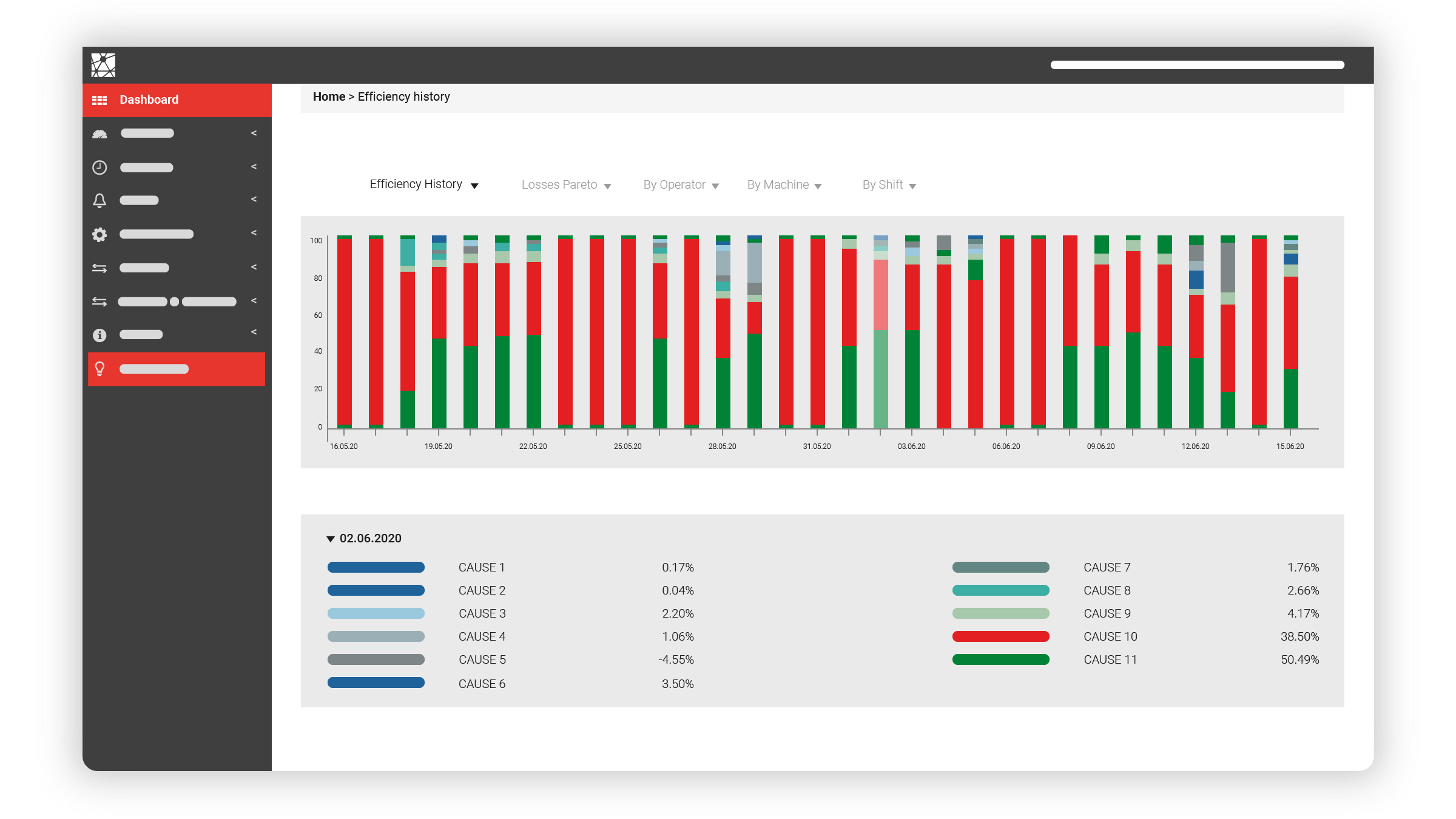

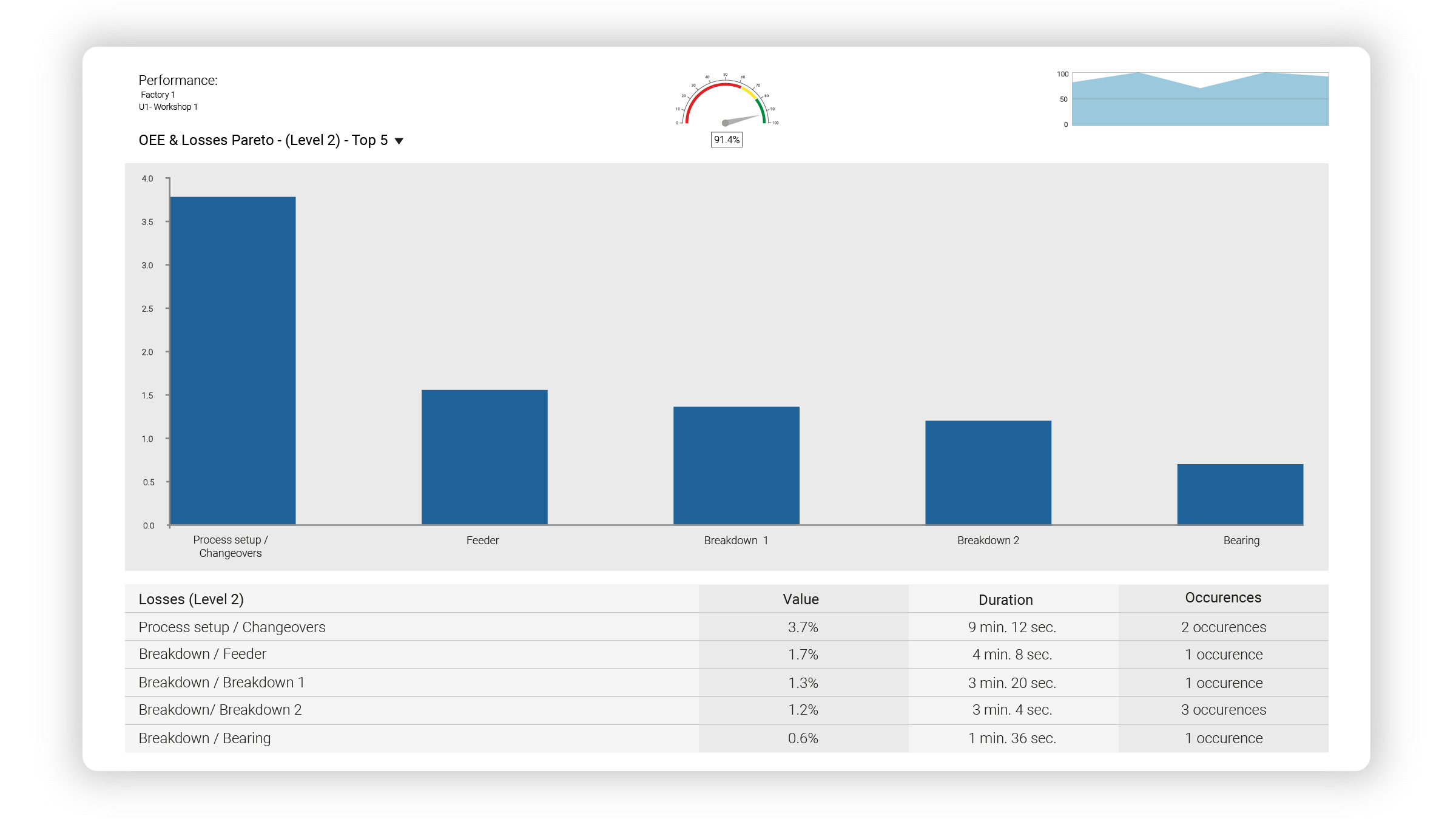

The supervision website

The supervision website, in addition to allowing the configuration of systems, brings together a set of ergonomic and intuitive functionalities, to enable teams to understand the causes of non-quality and act for continuous improvement.

Some features: real-time dashboards, performance history for the chosen scope and period, good or bad parts counting, manual and automatic reports, alarms by SMS or smartphone, etc.